Modern engineering is driven by the pursuit of precision, efficiency, and performance. As industries continue to demand lighter, stronger, and more reliable structures, advanced manufacturing and structural design techniques have become indispensable. Among these, laser cutting and monocoque construction stand out as two transformative technologies that are redefining how engineers design and fabricate high-performance systems. From aerospace and automotive engineering to advanced research and prototyping, these methods enable innovation that meets the rigorous demands of today’s engineering challenges.

Precision and Versatility of Laser Cutting

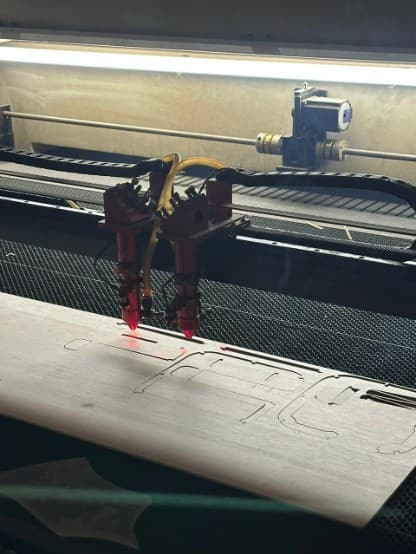

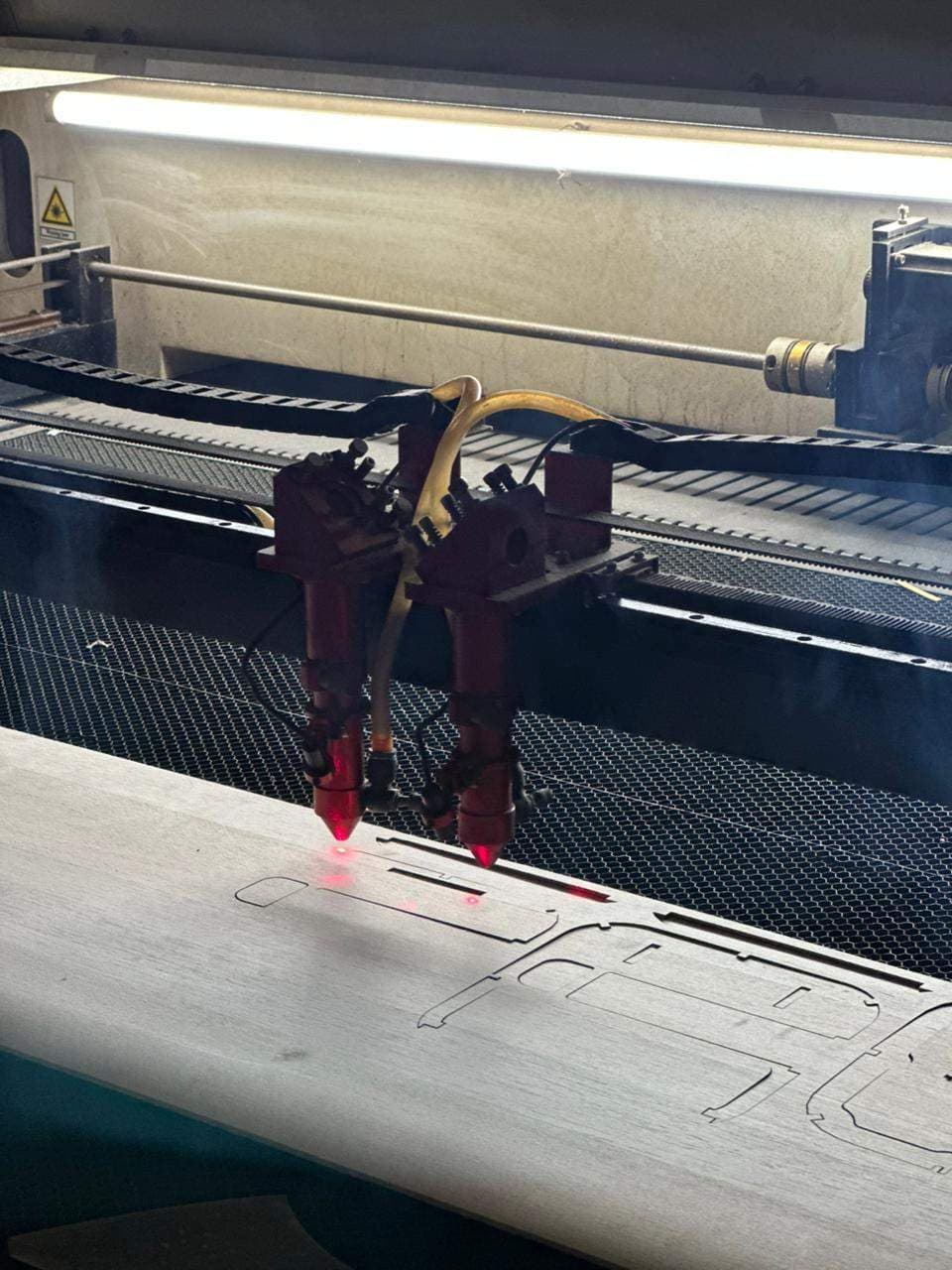

Laser cutting is widely recognized as one of the most precise and versatile manufacturing processes available today. By utilizing a high-powered, focused laser beam, materials can be cut with exceptional accuracy, ensuring clean edges and consistent dimensions. This level of precision is especially critical in aerospace and mechanical applications, where even minor dimensional inaccuracies can significantly impact performance.

Laser cutting supports a broad range of materials. Commonly processed metals include mild steel, stainless steel, aluminum, brass, and copper. In addition, non-metallic materials such as acrylic, wood, plywood, and composite sheets can be cut efficiently. For engineering applications that require lightweight and precise components, materials such as balsa wood and plywood are particularly effective, offering an excellent balance between strength, weight, and manufacturability.

Why Choose Laser Cutting?

• High Dimensional Accuracy: The process allows engineers to achieve tight tolerances and highly accurate geometries, significantly reducing the need for secondary finishing operations.

• Speed and Repeatability: Once programmed, laser cutting delivers consistent results across multiple components, making it ideal for both rapid prototyping and repeat production.

• Capability for Complex Geometries: Unlike conventional cutting methods, laser cutting can produce intricate shapes and fine details that would otherwise be difficult or impossible to achieve.

• Contactless Processing: As there is no direct mechanical contact with the material, the risk of deformation or mechanical stress is minimized, preserving structural integrity.

Despite its advantages, laser cutting does present certain challenges. Heat-affected zones can result in minor discoloration or warping, particularly in heat-sensitive materials. Reflective metals such as aluminum and copper require specialized laser systems, and proper ventilation is necessary to manage smoke and debris generated during cutting. However, with careful calibration, appropriate material selection, and controlled operating parameters, these challenges can be effectively mitigated.

Overall, laser cutting remains a cornerstone of modern fabrication, enabling engineers to transform digital designs into physical components with unmatched precision and efficiency.

Monocoque Structures: Strength Through Integration

Monocoque construction represents a fundamental shift in structural engineering philosophy. Rather than relying on a separate internal frame, a monocoque structure uses its outer shell as the primary load-bearing element. This integrated approach results in structures that are both lighter and stronger, making it especially valuable in performance-critical applications.

This construction method is widely used across multiple industries. In aerospace engineering, aircraft fuselages benefit from monocoque designs that provide strength without unnecessary weight. In automotive and motorsport applications, monocoque chassis deliver exceptional rigidity and safety. High-performance bicycles and marine structures also leverage this design approach to achieve superior structural efficiency.

Applications of Monocoque Structures

• Aerospace and Automotive Engineering: Aircraft fuselages, racing cars, and Formula vehicles rely heavily on monocoque construction to achieve optimal strength-to-weight ratios and enhanced safety.

• High-Performance Bicycles: Monocoque frames offer improved stiffness and durability, which are critical for competitive cycling and performance optimization.

Advantages of Monocoque Construction

• High Strength-to-Weight Ratio: By distributing loads across the outer shell, the structure achieves exceptional strength while minimizing overall weight.

• Improved Rigidity and Safety: The reduced number of joints and fasteners lowers the likelihood of structural weak points, enhancing durability and crash resistance.

• Enhanced Aerodynamics: Smooth, continuous surfaces reduce drag, which is particularly beneficial in aerospace and high-speed applications.

• Efficient Load Distribution: Forces are spread evenly across the structure, reducing localized stress concentrations and improving long-term reliability.

The manufacturing process of a monocoque structure involves careful design using CAD tools, precise material placement, and advanced fabrication techniques. Depending on the materials used—such as carbon fiber, fiberglass, or metal—processes may include bonding, vacuum bagging, autoclave curing, welding, or CNC forming. The result is a highly integrated structure capable of meeting stringent performance and safety requirements.

Synergy of Laser Cutting and Monocoque Structures

When laser cutting and monocoque construction are combined, they create a powerful synergy that elevates engineering outcomes. Laser cutting enables the precise fabrication of structural components, formers, and reinforcements, while monocoque construction integrates these elements into a unified, high-performance structure. Together, these technologies reduce manufacturing time, improve structural quality, and allow engineers to iterate on designs rapidly.

This integration is particularly valuable in aerospace design competitions and advanced research projects, where efficiency, accuracy, and performance are paramount. By leveraging the precision of laser cutting and the structural efficiency of monocoque construction, engineering teams can develop solutions that are lightweight, robust, and optimized for real-world performance.

As engineering continues to evolve, the adoption of advanced manufacturing and structural design techniques is no longer optional—it is essential. Laser cutting and monocoque construction exemplify how precision manufacturing and intelligent structural integration can work together to meet the demands of next-generation engineering. These technologies not only enhance performance and reliability but also empower engineers to push the boundaries of innovation, shaping a future defined by efficiency, strength, and intelligent design.